For small and medium-sized manufacturers, every hour of machine time counts. Unlike large enterprises that can absorb inefficiencies across multiple plants, a smaller operation often runs lean, with limited redundancy in equipment or staff. A single machine going down, or a production line running below capacity, can ripple through schedules, customer deliveries, and cash flow.

That’s why more plant managers are turning to Overall Equipment Effectiveness (OEE). Long seen as a tool for large-scale manufacturers, OEE has become accessible and practical for small to medium plants as digital tools and cloud-based systems make it easier to capture and analyze data. The value is clear: OEE provides a way to see, in one number, how effectively your equipment is running, and why it may not be performing to its potential.

This article explores what OEE means for small and medium plants, how to calculate it, common pitfalls, and practical steps to improve it without overwhelming your team.

What is OEE?

OEE is a standardized metric that measures how well equipment is being used compared to its full potential. It looks at three key factors:

- Availability: The percentage of scheduled production time that the equipment is actually running. Downtime events such as breakdowns, changeovers, or operator absence reduce availability.

- Performance: The speed at which the machine runs compared to its ideal cycle time. Small stops, reduced speed, or minor jams reduce performance.

- Quality: The proportion of good parts produced versus total parts made. Scrap, rework, or defects reduce quality.

The formula is straightforward:

OEE = Availability × Performance × Quality

For example, if your machine is available 90% of the time, running at 95% of its designed speed, and producing 98% good parts, your OEE is 0.90 × 0.95 × 0.98 = 83.7%.

This single number gives managers a clear view of how close they are to operating at peak efficiency.

Why OEE matters for small and medium plants

Large corporations have been using OEE for decades, often backed by sophisticated systems and dedicated improvement teams. For smaller manufacturers, the concept sometimes feels out of reach; another metric that requires resources they don’t have. But in practice, OEE may be even more valuable in smaller plants because:

- Every machine matters: Losing a critical press, CNC, or packaging line for half a shift can disrupt the entire plant.

- Cash flow is tighter: Inefficiency translates quickly into higher costs per unit, which smaller manufacturers can’t easily absorb.

- Customers expect reliability: Missed delivery dates or quality issues can damage relationships that took years to build.

- Growth depends on throughput: Before buying new equipment, many plants can unlock hidden capacity by improving OEE.

By focusing on OEE, small to medium plants gain visibility into where time and resources are lost, often without needing major new investments.

How to start measuring OEE

Measuring OEE doesn’t have to mean installing expensive machine monitoring systems. In fact, many small plants begin with manual tracking and gradually move toward automation. Here’s a practical roadmap:

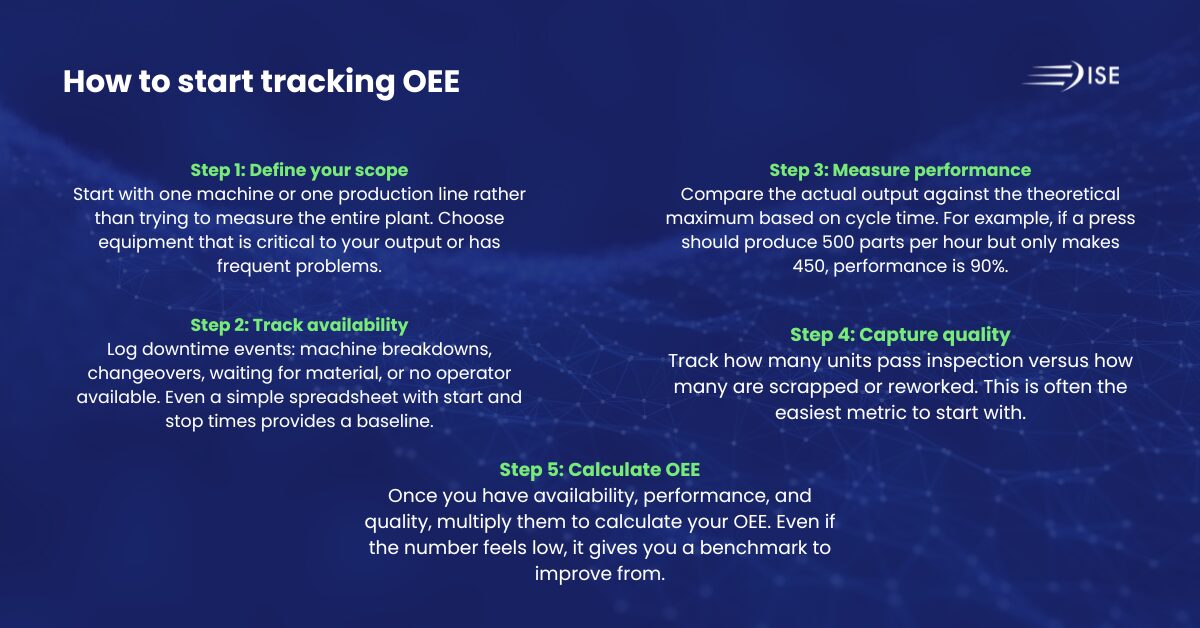

Step 1: Define your scope

Start with one machine or one production line rather than trying to measure the entire plant. Choose equipment that is critical to your output or has frequent problems.

Step 2: Track availability

Log downtime events: machine breakdowns, changeovers, waiting for material, or no operator available. Even a simple spreadsheet with start and stop times provides a baseline.

Step 3: Measure performance

Compare the actual output against the theoretical maximum based on cycle time. For example, if a press should produce 500 parts per hour but only makes 450, performance is 90%.

Step 4: Capture quality

Track how many units pass inspection versus how many are scrapped or reworked. This is often the easiest metric to start with.

Step 5: Calculate OEE

Once you have availability, performance, and quality, multiply them to calculate your OEE. Even if the number feels low, it gives you a benchmark to improve from.

What good OEE looks like

In theory, 100% OEE means your equipment runs nonstop at maximum speed with zero defects. In practice, world-class manufacturers often reach 85%. For small to medium plants just starting, it’s common to see OEE in the 50–70% range.

The goal is not to chase an abstract “perfect” number but to use OEE as a tool to identify the biggest opportunities for improvement. For one plant, it may be reducing long changeovers. For another, it may be cutting scrap in half.

Common pitfalls in OEE for smaller plants

While OEE is powerful, small and medium plants sometimes stumble when rolling it out. A few pitfalls to avoid:

- Overcomplicating the system: Trying to capture every detail from the start overwhelms operators and discourages adoption. Keep it simple at first.

- Focusing only on the number: OEE is a means to an end, not an end in itself. The goal is better performance, not just reporting.

- Ignoring operator input: Machines don’t tell the whole story. Operators often know the small stops, jams, and workarounds that data alone may miss.

- Treating OEE as a blame tool: If employees feel OEE is used to criticize, they’ll resist it. Position it as a way to improve processes, not punish people.

Practical ways to improve OEE

Once you start tracking OEE, the natural question is: how do we improve it? Here are some realistic, low-cost approaches for smaller plants:

Boost availability

- Standardize and streamline changeovers using SMED (Single-Minute Exchange of Dies) techniques.

- Implement simple preventive maintenance to reduce unplanned breakdowns.

- Ensure materials and tools are staged before production starts.

Improve performance

- Train operators on best practices for setup and operation.

- Investigate recurring small stops—are they caused by material, tooling, or machine settings?

- Set realistic but challenging production targets and track against them daily.

Increase quality

- Standardize work instructions to reduce variation between shifts.

- Perform in-process checks to catch defects early rather than at the end of the run.

- Analyze scrap data to identify root causes and eliminate repeat issues.

Using digital tools to make OEE easier

While OEE can begin with clipboards and spreadsheets, digital tools make it easier and more accurate. Many small and medium plants now use MES (Manufacturing Execution Systems) or lightweight machine monitoring solutions that integrate with ERP systems like Dynamics 365 Business Central.

These tools automatically collect production data, calculate OEE in real time, and display dashboards for operators and supervisors. Instead of waiting until the end of a shift, managers can see problems as they happen and take action.

Cloud-based solutions are particularly attractive for smaller plants because they avoid heavy infrastructure costs and scale as you grow. Even starting with just a few connected machines can provide insights that quickly justify the investment.

The bigger picture: OEE as a continuous improvement tool

The real power of OEE is not the number itself but the discipline it creates. By breaking down performance into availability, performance, and quality, it highlights where the biggest losses occur. Each improvement project can be tied back to one of these levers, making it easier to prioritize efforts.

For example:

- If availability is low due to frequent changeovers, focus on setup reduction.

- If performance is lagging, investigate machine speed and operator practices.

- If quality is poor, look at material consistency and process control.

Over time, OEE becomes part of the plant’s culture. Operators understand why it matters, managers use it to guide decisions, and executives see it as a reliable measure of operational health.

For small and medium plants, OEE is one of the most practical tools available to improve efficiency, reliability, and profitability. It provides a clear, structured way to measure how well equipment is performing and, more importantly, why it isn’t reaching its full potential.

Getting started doesn’t require expensive systems or massive teams. A simple pilot on one machine, tracked consistently, can uncover opportunities that pay back quickly. As digital tools become more accessible, scaling OEE across the plant is easier than ever.

In a competitive manufacturing environment, where customers expect shorter lead times and flawless quality, OEE gives smaller plants the ability to compete on more than just price. It helps them get the most out of the assets they already own, turning hidden capacity into real growth.