For years, Alexandria Industries faced a common manufacturing challenge: fragmented, inaccurate, and delayed data. Operators and managers often relied on manual updates and spreadsheets, making it difficult to track machine performance, production status, and scheduling in real time. This lack of visibility led to inefficiencies, longer response times, and missed opportunities for improvement.

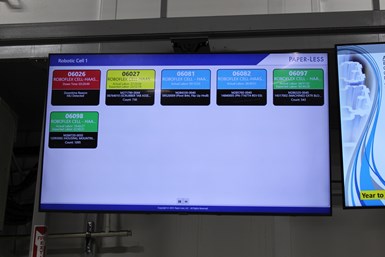

To overcome these pain points, Alexandria Industries implemented ISE’s MV2 Manufacturing Execution System (MES), creating a centralized data ecosystem that integrates seamlessly with FactoryWiz machine monitoring. FactoryWiz captures live machine data, while MV2 consolidates and translates that information into actionable insights for operators, supervisors, and ERP systems.

The impact has been transformative:

- Real-time visibility into machine utilization and production progress

- Accurate scheduling and resource planning, reducing downtime

- Elimination of manual data entry, minimizing errors, and freeing up staff

- Faster decision-making, thanks to dashboards and alerts that keep everyone informed

By connecting the shop floor to the top floor, MV2 and FactoryWiz have turned data into a strategic asset for Alexandria Industries, boosting productivity, improving transparency, and driving continuous improvement.

Want to learn how this integrated approach can help your operation? Read the full article on Modern Machine Shop.