Manufacturers constantly seek ways to increase efficiency, reduce waste, and boost throughput. One powerful leverage point is reducing setup or changeover time. Frequent changeovers negate much of the benefit of lean operations and can significantly impact production flow.

Digital sequencing, delivering guided, real-time, step-by-step setup instructions via a Manufacturing Execution System (MES), offers a modern, data-driven way to reduce changeover time in manufacturing. When combined with strong integration to planning systems (like ERP) and continuous improvement practices, it helps standardize setup, reduce errors, and accelerate production readiness.

In this blog, we’ll explore how digital sequencing helps manufacturers reduce changeover time, why it’s more effective than traditional approaches, and how MES platforms such as MV2 (from ISE) support this transformation. We’ll also reference key lean manufacturing principles and link to industry sources, Microsoft, and Infor to provide a well-rounded, credible discussion.

The Challenge: Why Changeovers Take Too Long

To understand the value of digital sequencing, it helps to first examine why changeovers often drag out:

- Operator variability

Different operators may perform setup tasks in different orders, skip steps, or rely on personal “tribal knowledge.” This variation leads to inconsistencies, rework, and quality issues. - Outdated or incomplete instructions

Printed standard operating procedures (SOPs) or binders on the shop floor often lag behind actual practice. When machine setups, tooling, or product designs change, paper documents may not reflect the current state. - Poor visibility of required tools and materials

Without clear guidance, operators may not know which jigs, fixtures, or materials they need for the next job, leading to wasted time gathering resources mid-setup. - No optimal sequencing

Without a defined, optimal sequence of steps, operators may perform tasks inefficiently, for example, doing items in a suboptimal order, causing repeated adjustments or backtracking. - Manual verification and recording

Using paper checklists or handwritten logs slows down verification, approvals, and data capture. Supervisors or schedulers may lack real-time visibility.

Disconnected planning systems

If the ERP or scheduling system does not communicate directly to the shop floor, operators may not know the correct setup instructions, especially for complex or variant-rich products.

Lean Foundations: SMED, 5S, and Process Improvement

Reducing changeover time is not a new problem; lean manufacturing has long addressed it with proven methodologies.

- SMED (Single-Minute Exchange of Die): This technique, developed by Shigeo Shingo, aims to reduce changeover times to a single minute. It involves separating internal (machine-stopped) and external (machine-running) tasks, converting internal tasks to external where possible, and rigorously standardizing and streamlining the remaining steps.

- 5S: Sort, Set in Order, Shine, Standardize, Sustain. These steps help organize the workspace so that tools and materials are always in the right place, reducing search time during changeovers.

- Value Stream Mapping (VSM): VSM allows teams to identify and eliminate non-value-added activities, including inefficient changeover steps.

While these lean tools remain powerful, they are even more effective when enabled by digital support, especially when combined with sequencing in a modern MES.

What Is Digital Sequencing?

Digital sequencing is the process of delivering detailed, guided setup workflows to operators through a digital interface, integrated with production systems.

Key characteristics:

- Step-by-step instructions accessible via tablets, terminals, or shop-floor monitors

- Visual aids (photos, diagrams, or even videos) to guide setup

- Pre-loaded lists of required tools, fixtures, materials, and quality checks

- Real-time data capture (timestamps, confirmations, measurements)

- Validation steps (e.g., torque, calibration, measurement) with required operator input

- Version control of sequences so that only the current, approved setup is used

- Live visibility for supervisors on progress, bottlenecks, and deviations

In a robust MES like MV2, offered by ISE, these sequences are linked directly to production orders, ensuring that the correct instructions for each product or variant are always delivered.

How Digital Sequencing Reduces Changeover Time

Digital sequencing addresses the root causes of long changeovers in several powerful ways:

- Standardization

By creating a consistent and optimized sequence for each setup, digital sequencing ensures that every operator follows the same high-quality workflow, reducing variation and eliminating rework. - Pre-changeover preparation

Sequences can include pre-setup tasks (external tasks) such as staging tools, jigs, or fixtures before the machine is stopped, which significantly shortens the downtime window. - Real-time operator guidance

Operators follow visually rich, intuitive instructions that reduce ambiguity. This reduces mistakes, prevents skipped steps, and accelerates the changeover process. - Built-in verification

Critical checkpoints (e.g., torque checks, calibration) can be embedded, and operators must confirm that these steps are taken. The MES logs this data automatically, improving traceability and first-pass yield. - Integrated data collection

As operators complete each step, the MES captures timestamps and data. This allows supervisors to see where delays are happening and improvement teams to analyze and refine the process. - Visibility and intervention

Supervisors or team leads can monitor in real time. If a sequence is taking too long, they can intervene, redirect resources, or provide support. - Seamless planning-execution alignment

Because the MES sequences are tied to production orders from the ERP, operators always receive the correct, current sequence. This reduces setup errors caused by miscommunication or outdated instructions.

Broader Value: Beyond Just Faster Changeovers

Reducing changeover time offers immediate benefits, but digital sequencing delivers additional long-term value:

- Increased throughput: Less downtime and fewer manual adjustments result in greater production capacity per shift.

- Reduced scrap and rework: Consistent setup quality yields fewer defects, especially at the beginning of a run.

- Faster onboarding: New or temporary operators follow guided workflows, reducing reliance on experienced staff.

- Better traceability and compliance: Every setup step and verification is digitally recorded, which supports audits and quality standards.

- Continuous improvement: Captured data enables analysis of setup step durations, bottlenecks, and common delay points, enabling targeted process improvement.

- Improved collaboration: Engineering teams can update sequences centrally, and the MES ensures that updated instructions propagate to all relevant workstations.

- Resource optimization: Pre-staging tools and materials reduces idle downtime and makes the changeover more efficient.

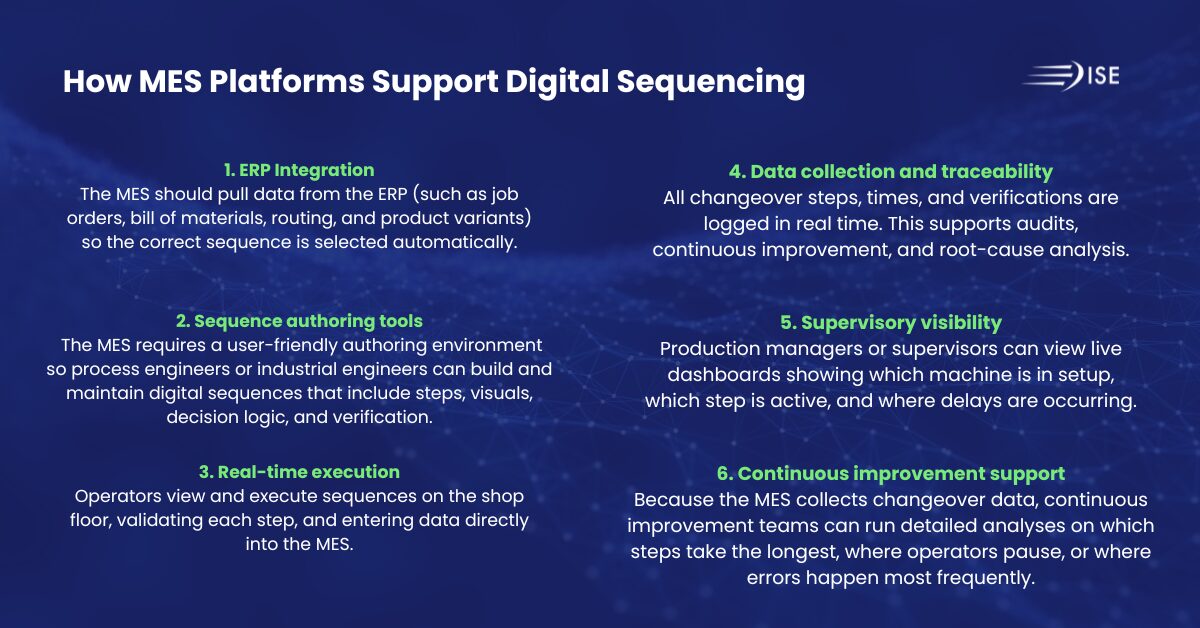

How MES Platforms Support Digital Sequencing

Not all digital tools are equal. True effectiveness requires an MES that integrates planning, execution, and continuous improvement.

Here’s how a well-built MES supports changeover reduction via sequencing:

- ERP Integration

The MES should pull data from the ERP (such as job orders, bill of materials, routing, and product variants) so the correct sequence is selected automatically. - Sequence authoring tools

The MES requires a user-friendly authoring environment so process engineers or industrial engineers can build and maintain digital sequences that include steps, visuals, decision logic, and verification. - Real-time execution

Operators view and execute sequences on the shop floor, validating each step, and entering data directly into the MES. - Data collection and traceability

All changeover steps, times, and verifications are logged in real time. This supports audits, continuous improvement, and root-cause analysis. - Supervisory visibility

Production managers changeover data, continuous improvement teams can run detailed analyses on which or supervisors can view live dashboards showing which machine is in setup, which step is active, and where delays are occurring. - Continuous improvement support

Because the MES collects steps that take the longest, where operators pause, or where errors happen most frequently.

MV2 supports digital sequencing across diverse manufacturing environments and integrates with major ERP platforms, including Infor XA and Microsoft Dynamics 365 Business Central. For more details, visit iseteam.com.

Digital Sequencing in the Context of Infor XA and Microsoft Business Central

Infor XA

For manufacturers using Infor XA, sequencing is especially powerful. XA is a mature, discrete-manufacturing ERP tailored for high-complexity environments. By integrating MV2 with XA, teams can seamlessly dispatch setup instructions based on XA production orders. This ensures tight alignment between planning and execution, ensuring setup consistency across the shop floor. Infor XA also supports standard process definitions and routings that can be leveraged by the MES when building and executing digital sequences.

Microsoft Dynamics 365 Business Central

If your manufacturing operation runs on Microsoft Dynamics 365 Business Central, MV2’s integration brings digital sequencing into a familiar ERP environment. Business Central supports routings, machine centers, and setup times in its production model.

On top of that, Business Central provides analytics tools for manufacturing. You can use Power BI or built-in reports to track production metrics, capacity, and more.

Further, Microsoft offers a Manufacturing Power BI app for Business Central that helps visualize shop floor KPIs, helping link changeover performance with broader production analytics.

For teams getting started with Business Central’s manufacturing functionality, Microsoft provides training paths that cover setting up BOMs, routings, and production orders.

Lean + Digital Sequencing: A Best-Practice Approach

To maximize impact, digital sequencing should complement lean methods, not replace them. Here’s a best-practice approach:

- Map your current state

Use value stream mapping (VSM) to document how changeovers currently occur. Identify internal vs external tasks, delays, and non-value-added work. - Apply SMED principles

Separate internal and external tasks, convert where possible, and standardize the remaining steps. Use visual tools (shadow boards, clear markings) to optimize setup. - Design digital sequences in the MES

Build your digital workflows in your MES (like MV2), using your lean-defined process as a guide. Include all setup tasks, materials, tools, and quality checks. - Train operators

Use digital sequencing during training and onboarding. Because operators follow the digital sequence, there is less reliance on verbal or tribal knowledge. - Track and analyze data

As operators execute sequences, they collect data on how long each step takes, where delays occur, and where operators deviate. - Improve continuously

Use the data to refine and optimize the sequence. Lean teams can identify bottlenecks or nonstandard behavior, then update the sequence to reflect better practice. - Maintain version control

Whenever processes, tooling, or product designs change, update the sequence in the MES authoring tool. Then push the new version to all relevant workstations.

Real-World Impact: What Companies Can Achieve

Here are some of the tangible outcomes manufacturers often realize when they adopt digital sequencing to reduce changeover time:

- Reduction in average setup times: Many companies move from highly variable setups to consistent, predictable changeovers, cutting time significantly.

- Less scrap and rework: Standardized sequences minimize alignment errors, calibration mistakes, and other issues that lead to quality defects.

- Higher utilization: More efficient changeovers mean more machine runtime and higher OEE (overall equipment effectiveness).

- Reduced training burden: New operators can follow digital instructions and ramp up faster, reducing reliance on senior operators for every changeover.

- Improved traceability: All setup activities and verifications are recorded digitally, ideal for audits, compliance, and continuous improvement.

Data-driven continuous improvement: The MES provides visibility into how actual changeovers perform versus planned, enabling targeted process improvements.

Risks and Considerations

Digital sequencing delivers many benefits, but there are important considerations to ensure success:

- Initial investment: You’ll need to invest in an MES, hardware (tablets or terminals), and sequence authoring.

- Change management: Operators and supervisors must adopt the new way of working, especially if they are used to paper-based instructions.

- Sequence maintenance: Processes evolve; if the MES sequences are not maintained, they can become obsolete or counterproductive.

- ERP integration: Proper integration between your MES and ERP (Infor XA, Business Central, etc.) is critical to ensure correct sequences are triggered.

Data overload: Capturing detailed timestamps and verification data is valuable, but organizations must have the capacity to analyze that data and act on insights.

Why ISE and MV2 Are Well-Positioned

At ISE, we understand that reducing changeover time is not just a shop-floor problem; it’s an enterprise-level opportunity. Our team brings deep experience implementing both ERP (Infor XA) and MES (MV2) systems, giving us a unique perspective on aligning planning and execution.

MV2’s digital sequencing capabilities are designed to help manufacturers:

- Build structured, guided workflows for every setup

- Capture key verification data and build full traceability

- Link to ERP orders so the right sequence is always used

- Provide live visibility into setup progress

- Enable continuous improvement via data-driven insights

Reducing changeover time in manufacturing is not just a lean ambition; it is a strategic, measurable lever for improving throughput, quality, and overall equipment effectiveness. Digital sequencing, when deployed in a modern MES environment, provides the structure, real-time guidance, and integrated data needed to eliminate variation, accelerate setup, and improve consistency.

By combining lean principles like SMED and 5S with a robust MES such as MV2, manufacturers can not only reduce setup time but also embed continuous improvement, traceability, and real-time visibility across the shop floor.

If your team is ready to move beyond printed instructions and unlock the power of digital sequencing, ISE can help.