For manufacturers, keeping production aligned with financial reality depends on accurate tracking of material usage. When consumption reporting is inconsistent, costs are difficult to reconcile, inventory levels drift from reality, and decision-making suffers. Microsoft Dynamics 365 Business Central offers several approaches to managing material consumption, with backflushing being one of the most common. While it simplifies shop floor reporting, it also raises critical questions about consumption accuracy in Business Central and how to achieve it.

This article explores what backflushing means in Business Central, how it compares with manual consumption posting, and how manufacturers can maintain accuracy while keeping reporting processes lean.

What is backflushing in Business Central?

Backflushing is an automated method of recording material consumption. Instead of manually reporting each component withdrawal from inventory, Business Central deducts the expected quantities automatically when a production order is finished or when an operation is posted.

The system uses the bill of materials (BOM) and routing to determine how much of each component should be used. When the order progresses, Business Central reduces inventory levels based on those expected quantities.

For example:

- A BOM specifies that producing one finished assembly requires four screws.

- If the order quantity is 100 assemblies, the system expects 400 screws.

- When production is posted, Business Central automatically deducts 400 screws from inventory.

This process reduces reporting burdens for operators while streamlining production order postings.

Why manufacturers choose backflushing

Many organisations adopt backflushing in Business Central because it reduces the need for manual shop floor reporting. Key benefits include:

- Efficiency: Operators focus on production rather than data entry.

- Simplification: Standard consumption rules are applied consistently.

- Speed: Finished goods and consumption are posted in one step.

- Control: BOMs and routings drive consistent calculations across all orders.

For high-volume, repetitive production environments, this method often aligns well with operational requirements.

The challenge of consumption accuracy in Business Central

While backflushing saves time, its accuracy depends entirely on how well BOMs and routings reflect reality. When actual consumption differs from expected, problems arise.

Common challenges include:

- Scrap or waste not accounted for in BOMs

- Substitutions made on the shop floor

- Variability in overconsumption or underconsumption

- Errors in setting up or maintaining BOMs and routings

These gaps affect more than operations. They lead to mismatched inventory levels, unreliable cost of goods sold (COGS), and excessive posting to variance accounts. Over time, they distort both financial reporting and supply chain planning.

Learn how ISE helps manufacturers address these challenges with Business Central solutions.

Manual consumption posting: the alternative

The alternative is manual consumption posting, where operators record the actual quantity withdrawn for each production order.

This method provides greater accuracy when:

- Material use is highly variable.

- Scrap rates fluctuate by batch or shift.

- Substitutions are frequent.

The trade-off is additional effort and potential delays in reporting. For this reason, many businesses adopt a hybrid model, backflushing for predictable items, and manual reporting for expensive or variable components.

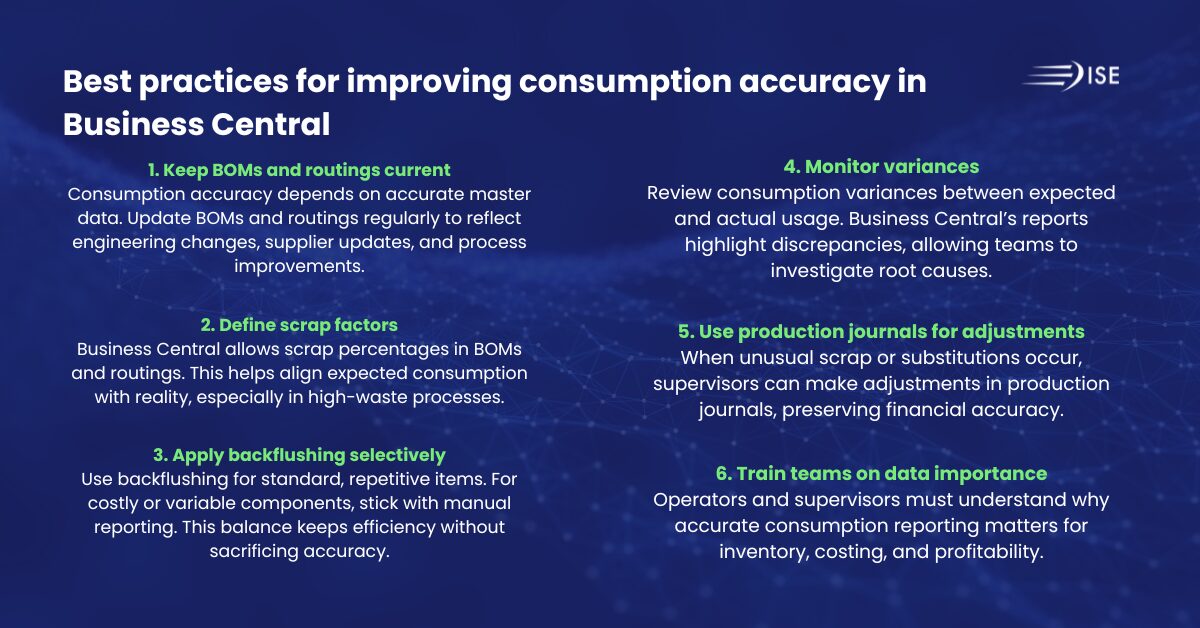

Best practices for improving consumption accuracy in Business Central

1. Keep BOMs and routings current

Consumption accuracy depends on accurate master data. Update BOMs and routings regularly to reflect engineering changes, supplier updates, and process improvements.

2. Define scrap factors

Business Central allows scrap percentages in BOMs and routings. This helps align expected consumption with reality, especially in high-waste processes.

3. Apply backflushing selectively

Use backflushing for standard, repetitive items. For costly or variable components, stick with manual reporting. This balance keeps efficiency without sacrificing accuracy.

4. Monitor variances

Review consumption variances between expected and actual usage. Business Central’s reports highlight discrepancies, allowing teams to investigate root causes.

5. Use production journals for adjustments

When unusual scrap or substitutions occur, supervisors can make adjustments in production journals, preserving financial accuracy.

6. Train teams on data importance

Operators and supervisors must understand why accurate consumption reporting is crucial for inventory management, costing, and profitability.

Financial impact of inaccurate consumption

Errors in consumption reporting ripple through the entire financial system:

- Overstated or understated COGS distorts profitability analysis.

- Unreliable inventory valuation affects balance sheets.

- Variance accounts can mask operational inefficiencies.

For CFOs and controllers, accurate consumption is not optional. It ensures financial transparency and reliable decision-making.

Explore how accurate reporting improves finance and operations alignment in our ISE industry solutions.

Business Central tools that support accuracy

Microsoft Dynamics 365 Business Central provides several features to balance efficiency with accuracy:

- Flexible flushing methods: Each BOM component can be set to manual, forward, backward, or pick + backward flushing.

- Routing-linked flushing: Materials can be consumed at the operation level, not just at order finish.

- Variance and consumption reporting: Standard reports identify discrepancies between expected and actual usage.

- Integration with warehousing: For companies using advanced warehouse features, picking processes can link directly with consumption posting.

You can find detailed technical documentation on Microsoft Learn.

Striking the right balance

Backflushing is neither a cure-all nor a risk to be avoided. The best approach often combines automated consumption for predictable materials with manual entry for items where accuracy is critical.

Practical recommendations include:

- Backflush low-cost, high-volume items.

- Manually post expensive or variable materials.

- Review and update BOMs regularly.

- Track variances and act quickly on discrepancies.

This balance delivers both shop floor efficiency and financial reliability.

Broader context: consumption accuracy as a strategic priority

When organisations treat consumption accuracy as a strategic requirement, they move beyond firefighting variances. They gain the ability to:

- Plan production with confidence.

- Strengthen financial transparency.

- Improve supplier negotiations by understanding true material usage.

- Enhance decision-making at the executive level.

As industry commentators on ERP Software Blog and MSDynamicsWorld often highlight, businesses that integrate operational and financial accuracy outperform those that manage them in silos. Business Central provides the flexibility to make this integration possible.

Key takeaways

- Backflushing automates material consumption posting but depends on accurate BOMs and routings.

- Consumption accuracy in Business Central requires scrap factors, variance monitoring, and selective use of backflushing.

- A hybrid approach is often the most effective, balancing efficiency with reliability.

- Business Central provides the tools needed, but discipline in process and training are just as important.

By focusing on both backflushing and consumption accuracy, manufacturers can trust their data, reduce costly surprises, and make better decisions across operations and finance.

Learn how ISE can help streamline your manufacturing reporting in Dynamics 365 Business Central.